Sheet Extruder Application and Maintenance Manual

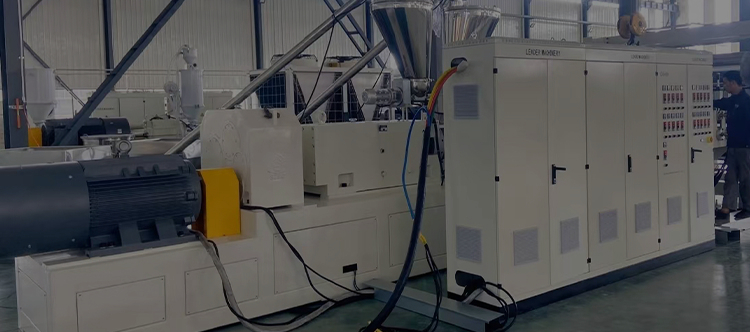

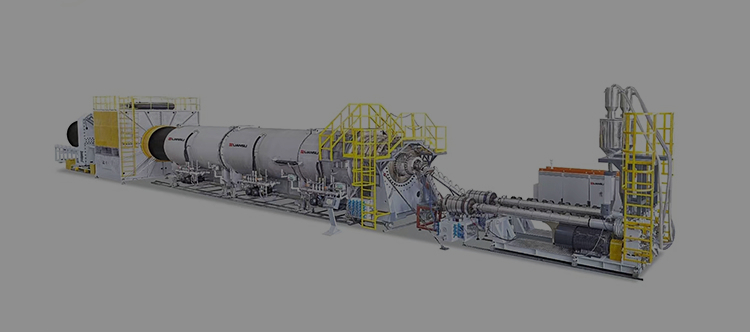

sheet extruder is an electronic, food, pharmaceutical packaging industry essential to a machine equipment, it can be heated and melted plastic raw materials through the mold extrusion molding, so as to make a variety of exquisite packaging containers. With the plastic products manufacturers on the quality of the increasingly high requirements, more and more widely used, then the use of these equipment in the long-term high-speed operation of the production and manufacturing process, there is bound to have a certain grasp of the characteristics of the machine and equipment, the following is the application and maintenance of sheet extruder.

1. application

sheet extruder is mainly used in the production of plastic sheets, such as PET, PP, PE and other materials. It can heat and melt the plastic raw material, extrude it into a sheet through a die, and then perform subsequent processing such as cooling and winding. The sheet extruder is suitable for food packaging, medicine, electronics, construction and other fields.

2. maintenance

In order to ensure the normal operation and prolong the service life of the sheet extruder, regular maintenance is required. The following is the specific content of sheet extruder maintenance:

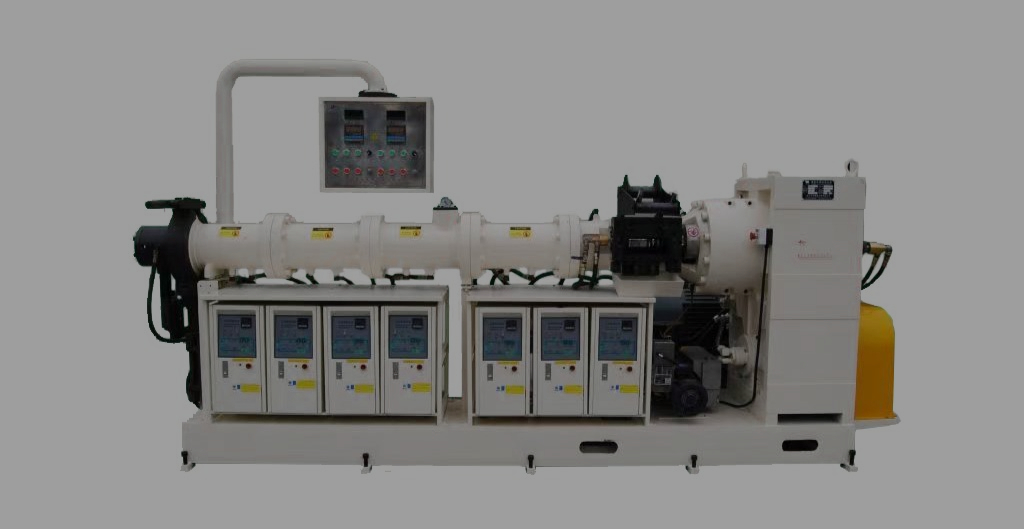

- Regularly check the transmission parts of the equipment, including gears, bearings, transmission belts, etc., to ensure that they are in good working condition.

- Regularly check the hydraulic system of the equipment, including hydraulic pumps, hydraulic cylinders, hydraulic pipelines, etc., to ensure that they are free of leakage and blockage.

- Regularly check the electrical system of the equipment, including motors, cables, electrical cabinets, etc., to ensure that they are working properly.

- Clean and maintain the equipment regularly to keep the equipment clean and sanitary.

- Regularly check the mold part of the equipment, including the wear and deformation of the mold, and repair and replace it in time.

- Regularly lubricate and maintain the equipment to maintain the lubrication of the equipment and the normal operation of the mechanical parts.

- Check and maintain the control system of the equipment regularly to ensure the normal operation of the control system of the equipment.

- When the equipment is not used for a long time, the equipment should be stored in a dry and ventilated place, and the equipment should be inspected and maintained regularly.

In short, the maintenance of the sheet extruder is very important. It can not only ensure the normal operation of the equipment and extend the service life of the equipment, but also improve the work efficiency and product quality of the equipment. Therefore, it is recommended that the use of units regularly carry out equipment maintenance work, and establish a sound maintenance system.