PET sheet extruder?

PET sheet extruder is affected by many factors, including equipment size, design structure, process parameters, raw material quality, etc. In general, the maximum output of the PET sheet extruder can reach about 1.5 tons per hour.

However, it should be noted that the maximum output of the equipment cannot be maintained all the time, and is affected by many factors, such as equipment running time, operator skill level, production environment, etc. Therefore, in order to improve the output of PET sheet extruder, it is necessary to comprehensively consider various factors and take corresponding measures to optimize and improve.

To increase the output of PET sheet extruder, the following measures can be taken:

- Increase raw material reserves: Extruder production requires a large amount of raw material support, so increasing the amount of raw material reserves can effectively improve production efficiency. Adequate raw materials can be purchased from raw material suppliers and a reasonable storage system can be established to ensure that sufficient raw materials can meet production needs, reduce waiting time, and increase production.

- Optimize the production process: By adjusting the process parameters of the extruder, such as temperature, pressure, speed, etc., the production process of PET sheets can be optimized and the output can be increased.

- Regular maintenance and maintenance: Regular maintenance and maintenance of the extruder can ensure the normal operation of the equipment and improve production efficiency.

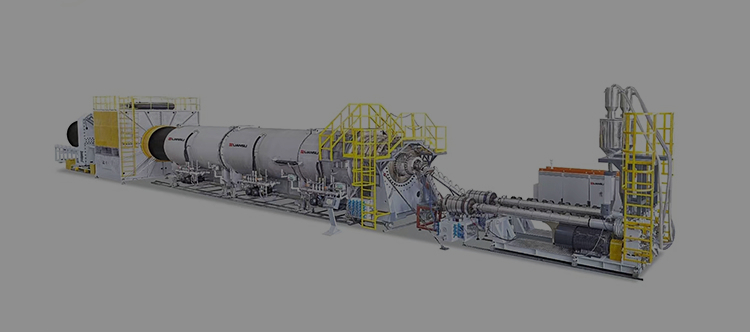

- Increase the size of the equipment: By increasing the size of the extruder, the output of PET sheets can be increased. However, it should be noted that the increase in the size of the equipment will also lead to an increase in cost, which needs to be considered comprehensively.

- Introducing automation technology: By introducing automation technology, such as robots, sensors, etc., manual operations can be reduced and production efficiency can be improved.

- Optimize product design: By optimizing the product design of PET sheet, such as thickness, shape, structure, etc., the quality of the product can be improved, thereby indirectly increasing the output.

To sum up, to improve the output of PET sheet extruder needs to start from many aspects, including raw material reserves, production process, equipment maintenance, equipment size, automation technology and product design.