-

-

PET sheet extruder?

PET sheet extruder is affected by many factors, including equipment size, design structure, process parameters, raw material quality, etc. In general, the maximum output of the PET sheet extruder can reach about 1.5 tons per hour.

넶0 2023-12-25 -

what method can reduce the barrel screw wear?

1. Select small particle recycled material processing:

For the guide rotating twin screw, the material should be transported along the axial direction, just like a pair of calender rolls. The screw is subjected to outward and upward forces, then the screw is pushed onto the barrel, causing the barrel screw to wear, especially when processing materials.넶0 2023-11-24 -

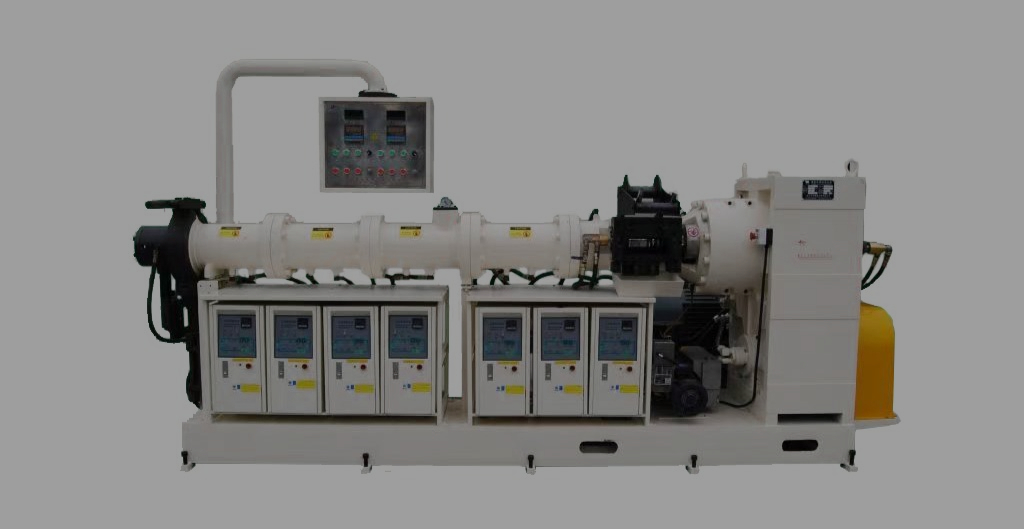

rubber equipment

rubber extruder mainly plays the role of extrusion molding in the production of rubber products. Before production, we should select the type and quantity of equipment used in production according to the size and structure of the product. For example, in the production of rubber sealing strip, sometimes only one rubber extruder is needed to extrude the product, while in some cases, two or more rubber extruders must be used to extrude the product together.

넶0 2023-09-21 -

Twin Screw Extruder

twin screw extruder host a zone temperature is too low:

1. Temperature control meter fails: whether the OUT1 lamp in the low temperature section is on.

2. If the stop valve is too large, disassemble the electromagnetic valve core and blow it with an air pump.

3. The heater power is too small or the heater half is damaged or short-circuited.넶0 2023-02-17 -

TPU Polymerization

The selection of the displacement coefficient of the TPU polymerization twin-screw extruder should be based on the specific design requirements. Because the influence of different displacement coefficients on the contact strength and bending strength of the gear is different, the displacement coefficients of the gear can be taken into the same, which is easy to calculate in the series design and is not easy to make mistakes. It is better to use all angular displacement and make the sum of the di

넶0 2022-10-27 -

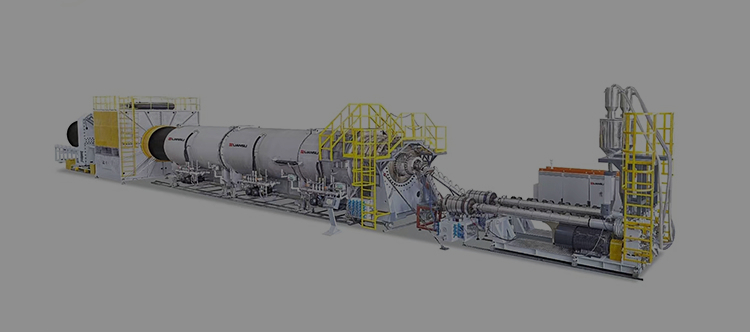

Planetary Single Screw Sheet Extruder

planetary single screw sheet extruder is: in the middle section of the screw of the extruder (I. e. plasticizing section) or the entire screw (only the feeding section of the feeding part is not a planetary screw) is a planetary screw structure. When working, the central screw is used as the active screw, and its outer circle has a plurality of small-diameter screws meshing with it. These small-diameter screws can rotate on their own and revolve around the central screw. This is because the oute

넶0 2021-08-19

-

-

-

Twin Screw Sheet Extruder

twin-screw sheet extruder is to melt, mix and extrude solid materials through the interaction of two rotating screws. In a twin-screw extruder, the two screws intermesh with each other during rotation, resulting in intense mixing and shearing. The material enters through the hopper of the twin-screw extruder and is brought into the barrel of the extruder under the rotation of the screw. In the barrel, the rotation and meshing of the screw and the heating or cooling according to the characteristi

넶0 2019-08-29 -

Sheet Extruder Application and Maintenance Manual

sheet extruder is an electronic, food, pharmaceutical packaging industry essential to a machine equipment, it can be heated and melted plastic raw materials through the mold extrusion molding, so as to make a variety of exquisite packaging containers. With the plastic products manufacturers on the quality of the increasingly high requirements, more and more widely used, then the use of these equipment in the long-term high-speed operation of the production and manufacturing process, there is bou

넶0 2020-08-06 -

Planetary Single Screw Sheet Extruder

planetary single screw sheet extruder is: in the middle section of the screw of the extruder (I. e. plasticizing section) or the entire screw (only the feeding section of the feeding part is not a planetary screw) is a planetary screw structure. When working, the central screw is used as the active screw, and its outer circle has a plurality of small-diameter screws meshing with it. These small-diameter screws can rotate on their own and revolve around the central screw. This is because the oute

넶0 2021-08-19 -

TPU Polymerization

The selection of the displacement coefficient of the TPU polymerization twin-screw extruder should be based on the specific design requirements. Because the influence of different displacement coefficients on the contact strength and bending strength of the gear is different, the displacement coefficients of the gear can be taken into the same, which is easy to calculate in the series design and is not easy to make mistakes. It is better to use all angular displacement and make the sum of the di

넶0 2022-10-27 -

Twin Screw Extruder

twin screw extruder host a zone temperature is too low:

1. Temperature control meter fails: whether the OUT1 lamp in the low temperature section is on.

2. If the stop valve is too large, disassemble the electromagnetic valve core and blow it with an air pump.

3. The heater power is too small or the heater half is damaged or short-circuited.넶0 2023-02-17 -

rubber equipment

rubber extruder mainly plays the role of extrusion molding in the production of rubber products. Before production, we should select the type and quantity of equipment used in production according to the size and structure of the product. For example, in the production of rubber sealing strip, sometimes only one rubber extruder is needed to extrude the product, while in some cases, two or more rubber extruders must be used to extrude the product together.

넶0 2023-09-21

-

-

PET sheet extruder?

PET sheet extruder is affected by many factors, including equipment size, design structure, process parameters, raw material quality, etc. In general, the maximum output of the PET sheet extruder can reach about 1.5 tons per hour.

2023-12-25

-

what method can reduce the barrel screw wear?

1. Select small particle recycled material processing:

For the guide rotating twin screw, the material should be transported along the axial direction, just like a pair of calender rolls. The screw is subjected to outward and upward forces, then the screw is pushed onto the barrel, causing the barrel screw to wear, especially when processing materials.2023-11-24