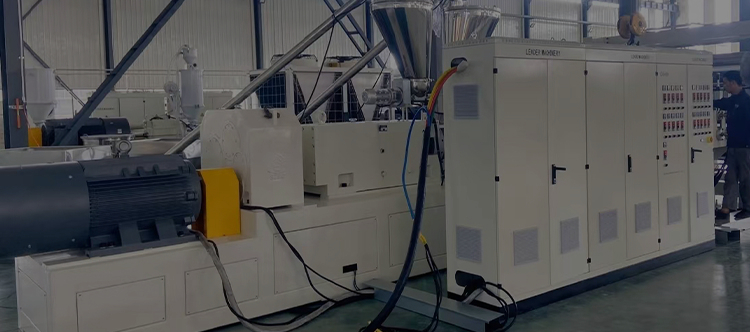

Twin Screw Sheet Extruder

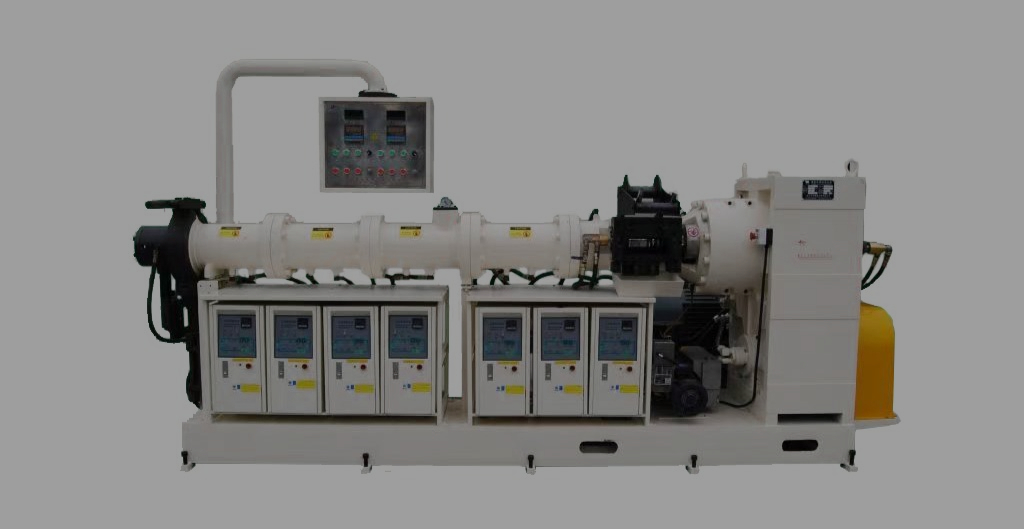

twin-screw sheet extruder is to melt, mix and extrude solid materials through the interaction of two rotating screws. In a twin-screw extruder, the two screws intermesh with each other during rotation, resulting in intense mixing and shearing. The material enters through the hopper of the twin-screw extruder and is brought into the barrel of the extruder under the rotation of the screw. In the barrel, the rotation and meshing of the screw and the heating or cooling according to the characteristics of the material melt or solidify the material.

, when the material passes a certain distance between the screws, mixing and shearing will occur, so that the bonds between the molecules of the material are broken and recombined to form a uniform mixture. In this process, pressure is constantly applied to the outside to extrude the material to the outlet of the extruder. The final product shape depends on the die of the extruder, such as a twin-screw extruder for the production of plastic films, the outlet of which is mounted on a cylindrical die to form a plastic film of infinite length.

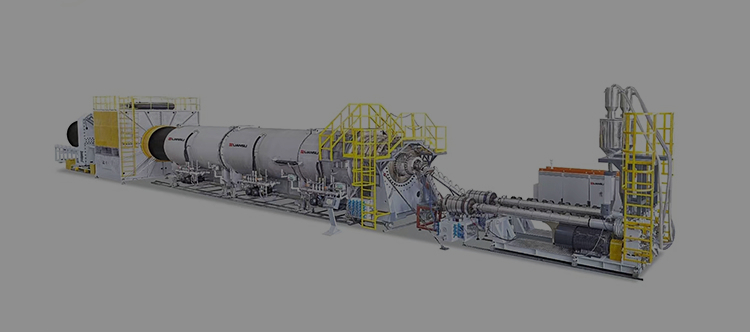

Twin-screw extruder is mainly used in the plastic molding industry. For high-performance, high-viscosity and high deformation temperature raw materials, such as PVC, PA, PC, PP, PE, etc., its extrusion processing effect is obviously better than that of single-screw extruder. The twin-screw extruder can fully mix the raw materials during the extrusion process, increase the melting degree and melting uniformity, reduce the phase decomposition and deterioration during the extrusion process, thereby improving the extrusion efficiency and the quality of the finished product.

In addition, for rubber, a polymer material, its extrusion processing is often limited by flow and mixing, thus affecting the quality of the finished product. Compared with the single screw extruder, the twin screw extruder has higher mixing and extrusion capacity, can reduce the temperature fluctuation and energy loss in the mixing process, and improve the uniformity of the extrusion speed and the shape of the product. Especially for rubber materials with high hardness, high viscosity, high strength and high processing difficulty, it has more superior processing performance.

twin screw extruder has the extruder principle of a single screw extruder, including the steps of solid conveying, melting, pressurizing and pumping, mixing, stripping and devolatilization. However, the twin-screw extruder is not simply a combination of these steps, but through the special working mode of the twin screw, the various steps are organically combined together to form a continuous production process.