TPU Polymerization

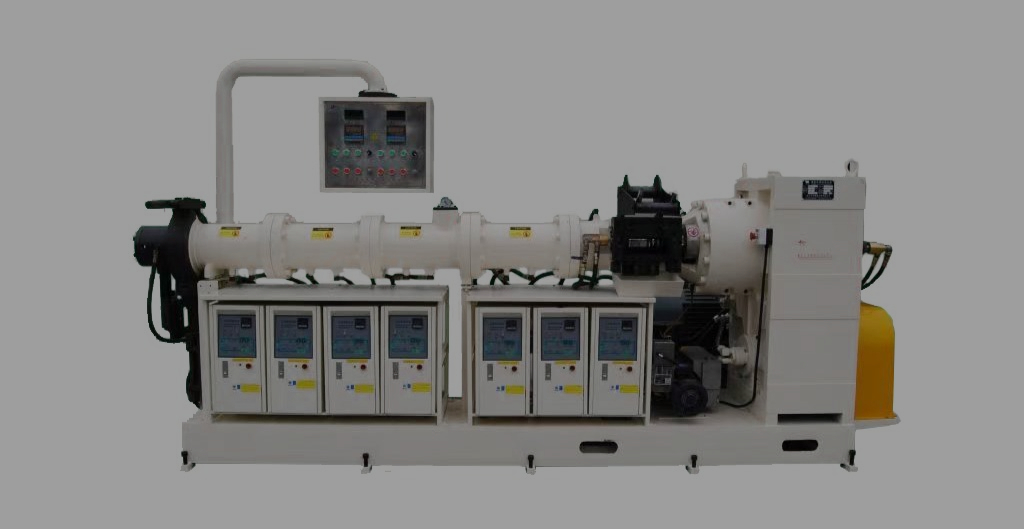

The selection of the displacement coefficient of the TPU polymerization twin-screw extruder should be based on the specific design requirements. Because the influence of different displacement coefficients on the contact strength and bending strength of the gear is different, the displacement coefficients of the gear can be taken into the same, which is easy to calculate in the series design and is not easy to make mistakes. It is better to use all angular displacement and make the sum of the displacement coefficients greater than 0, which can improve the bending strength of the tooth root. Reduce the sub-box surface of the transmission box as much as possible, and at the same time pay attention to the geometric dimensions of the two directions of the horizontal plane of the box not too large.

reduce the transmission chain as much as possible. The increase in the number of transmission chains means that the number of transmission mechanisms increases, and the overall geometry of the transmission system increases, resulting in an increase in other problems.

Considering the strength and the continuity of the series, the number of teeth and the modulus of change in the same center distance should be reduced from large to small, and should not be reduced by jumping. The helix angle should make the high speed take the large value and the low speed take the small value, so that the high-speed axial coincidence degree increases, achieves stable operation, reduces the low-speed axial force, and improves the service life of the bearing. The speed ratio distribution should be non-integer, which takes into account that if the processed gear is defective, it will not appear in the same part of the paired gear during operation.